Your product can never be better than the mix!

Separating the preparation process from the transportation of the material to be mixed during that process allows the speed of the mixing tool (and thus the power input into the mix) to be varied within wide limits.

The mixing tool can run at variable speeds, from fast to slow. This allows the power input into the mixture to be adapted to the specific mix.

‘Hybrid’ mixing processes are possible, e.g. slow – fast – slow.

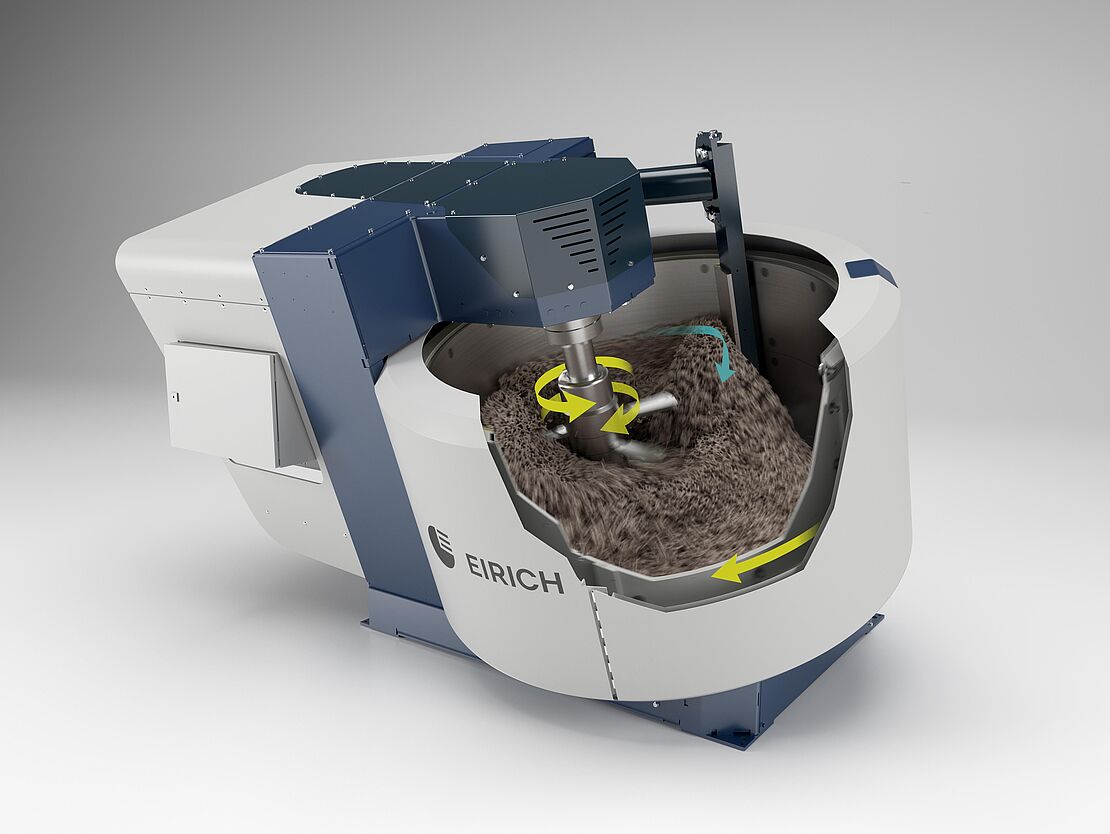

The special Eirich mixing system comprises just 3 components. These components can be adapted particularly flexibly to the specific requirements of the mixing processes.

- The rotating mixing pan, which moves the mix into the path of the mixing tools.

- One or more mixing tools arranged eccentrically, the direction of rotation and the speed of which can be optimally adapted to the different applications.

- The bottom/wall scraper, which adds additional movement to the flow of the mix and prevents caking on the wall or bottom of the pan, as well as aiding the discharge of the mix at the end of the mixing cycle.

Benefits of the mixing system

The benefits for the product being mixed:

- High tool speeds ensure that

- fibers are solubilized to optimum effect

- pigments are completely pulverized

- fines are mixed to optimum effect

- suspensions with a high solids content are produced - Medium tool speeds

- are for producing high-quality mixes - Low tool speeds

- allow lightweight additives or foams to be added gently to the mixture - The mixer mixes without separating the mixture, so 100% of the material is agitated in one revolution of the mixing pan

The benefits for production:

- The robust design and construction guarantee excellent service life and high availability

- Wearing elements are readily accessible, making them easy to replace

- Seals are not impinged directly with mixing material

Eirich customers report:

- Rapid and high-quality processing of materials of every type and consistency

- Better distribution of additives

- Scrap rates significantly reduced

- Much less wear

- Significantly greater availability

Unlike all other mixing systems, the throughput rate and mixing intensity of Eirich’s intensive batch mixers can be set independently of each other.

- The mixing tool can run at variable speeds, from fast to slow

- This allows the power input into the mixture to be adapted to the specific mix

- ‘Hybrid’ mixing processes are possible, e.g. slow – fast – slow

- High tool speeds ensure, for instance, that

- fibers are solubilized to optimum effect

- pigments are completely pulverized

- fines are mixed to optimum effect

- suspensions with a high solids content are produced - Medium tool speeds are for producing high-quality mixes

- Low tool speeds allow lightweight additives or foams to be added gently to the mixture

The mixer mixes without separating the mixture, so 100% of the material is agitated in one revolution of the mixing pan.

Eirich’s intensive batch mixers are available in two model series with effective volumes of 1 to 12,000 liters.

Unlike all other mixing systems, the throughput rate and mixing intensity of Eirich’s intensive continuous mixers can be set independently of each other. The ability to

- vary the rotational speed of the mixing tools

- vary the rotational speed of the mixing pan

- precisely adjust the dwell time in the mixing process

has a particularly advantageous effect on the overall result. Even while the mixing processes are starting, no unmixed or partially mixed material can leave the mixer.

Eirich’s intensive mixers can be designed to allow operation under vacuum. The vacuum mixer range offers all the advantages of the intensive mixer, but also enables additional process steps to be performed in one machine, e.g.

- ventilation

- drying

- cooling or

- heat dissipation in exothermic reactions

for applications across a wide range of industries.

Technologies for

- foundry molding sand

- lead paste compounds for batteries

- high-density granules

- aqueous sludges or sludges containing solvents

- metalliferous sludges

- friction linings

- soaps

Vacuum mixers are available with effective volumes of 1 to 7,000 liters.

Evacmix®

is used for processes in which deaeration is used to achieve compounds with a particularly high density.

EVACTHERM®

is a system for thermal processes (cooling/drying) which has been very successful at a global level.

SAPONIFLEX®

is a compact system which offers exceptional flexibility and efficiency in the manufacture of soaps.