Mixing

Granulating & pelletizing

Coaten

Dry/wet grinding & classifying

Kneading

Dispersion

Temperature regulation

Drying & reacting

The individual processes in detail

Mixing to perfection - homogenizing multiple materials

Benefits

- Complete disintegration of agglomerates

- Maximum homogeneity even with large differences in density

- Separation of the mixture avoided

Examples of applications

- Concrete

- Dry mortar

- Sand-lime bricks

- and many more

Granulating & pelletizing - getting powder into shape

Granules are created when individual particles are built up in layers to form a solid bond. With the unique Eirich mixing principle and disk pelletizers, this can be done perfectly and in ultrafast time.

Benefits

- Manufacture of granules (0.2 mm – 5 mm) in the mixer or pellets in the centimeter range with the disk pelletizer

- Formation of particularly stable and abrasion-resistant granules

Examples of applications

Coating - when the look & feel differ from the content

Minimal quantities of liquids or solids are distributed over the solid surfaces through the application of sufficiently high shear forces. With the unique Eirich mixing principle, this can be done perfectly in ultrafast time.

Benefits

- Targeted functionalization

- Coating of granules or coarse input materials

Examples of applications

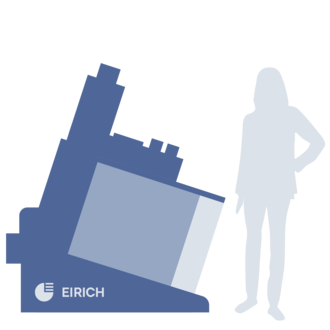

Dry/wet grinding & classifying - in Eirich mills from small to large

Eirich offers a range of mill types for dry or wet grinding brittle materials. The addition of classifying technology turns them into the optimum system concept.

Advantage

- Grinding soft to very hard materials

Examples of applications

- Frits

- Silica sand

- Fillers

- and many more

Kneading - bringing energy into your mixture

Kneading and plasticizing involves the uniform wetting of dry raw material components with liquids to produce an end-product which is plastic in form.

With the unique Eirich mixing principle, this can be done perfectly and in ultrafast time.

Benefits

- Maximum homogeneity of the mixing material

- Very short processing times compared to kneading (minutes rather than hours)

Examples of applications

Dispersion - ideal distribution of the solution

In the Eirich mixer, the suspension is produced in a single pot process involving the continuous addition of liquid to what is initially a dry phase which subsequently becomes plastic, along with further dilution.

Benefits

- Short processing times (minutes rather than hours)

- Any desired suspension viscosity can be achieved

- Saves on additives

Examples of applications

Precise temperature regulation in the mixing process

With the double-walled mixing pan from EIRICH

In many processes it is the temperature that determines the quality of product. That is the case with sensitive slurries, for instance, chemical reactions and moisture-dependent granules. With the optional double-walled mixing pan, EIRICH offers the possibility of controlling the temperature of the mixture – cooling it down or heating it up, depending on the process requirement.

The temperature is controlled by means of an integrated double jacket through which heating or cooling media (e.g. water, glycol or thermal oil) circulate. This allows the product temperature to be controlled continuously and reproducibly – even under intensive mixing and shear stresses. Typical temperature ranges are between +5 °C and +95 °C, depending on the medium and system configuration.

In contrast to conventional mixing systems, the energy input in the EIRICH principle remains controllable at all times: The rotating pan ensures that the material flows evenly, while the mixing tool – which is driven separately – inputs the specific energy required. This means that the heat is distributed homogeneously in the product – without localized overheating or any loss of quality.

The system can optionally be expanded with additional heating processes, such as superheated steam, hot air, infrared or induction heating. Temperature sensors in the mixing chamber enable precise regulation and seamless process documentation.

The result is exact temperature regulation, maximum process stability, reproducible results and consistent product quality – even with the most demanding raw materials and methods.

Benefits at a glance:

- Process-driven temperature regulation thanks to the double-walled pan

- Heating and cooling with water, oil or steam, depending on the application

- Homogeneous heat distribution under the unique EIRICH principle

- Controllable temperature profiles for lab, pilot and production scales

- Optimum product quality with temperature-sensitive mixing materials

Typical applications:

- Battery slurries

- Ceramic slips

- Chemical reaction mixes

- Pharmaceutical and cosmetic products

- Adhesives

- Sealing and casting compounds

Drying & reacting - temperature and atmosphere under control

With the appropriate peripheral equipment, the Eirich mixer can be used for drying and also controlling solid-solid and solid-liquid reactions.

Benefits

- Atmospheric or vacuum drying using hot air, inert gases or hot steam

- With or without explosion protection

Examples of applications

- Pesticides

- Friction linings

- Industrial sewage sludge

- and many more